My dream of a mic is a Neumann M49. So I decided to build something vaguely similar, albeit using a simple FET circuit. I'm thinking about a tube version, though.

The capsule is a Dale M7, the transformer is one of those "BV-style" Giantbenny ones. They're about 10:1, so I decided on a simple KM84 style one FET circuit. There's nothing really new or particularly interesting about "my" mic design. The reason I'm showing it here is the mechanical part, which may inspire some of you guys. In particular the M7 capsule mount that some of you may be struggeling with. It took me a while to come up with a simple solution.

As you see, it's just a V-shaped brass profile bent to a kind of omega shape, which then slides into a copper tube. A long M3 screw presses down on the brass profile, thus fixing it. The screw of course is also used to fix the mount on the base plate, which is just perfboard. I used a rubber thingy which in fact was a capsule holder for a small electret mic capsule (any piece of rubber tube may do just as well). This rubber thingy makes the mount a little flexible which helps to reduce rumble.

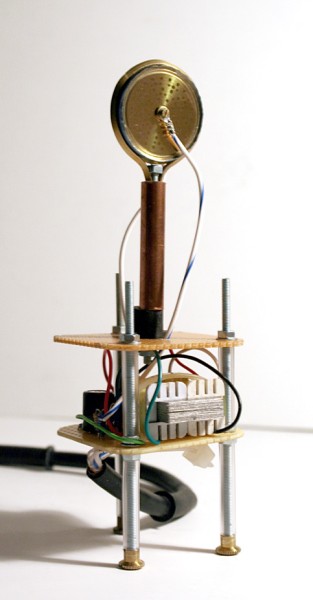

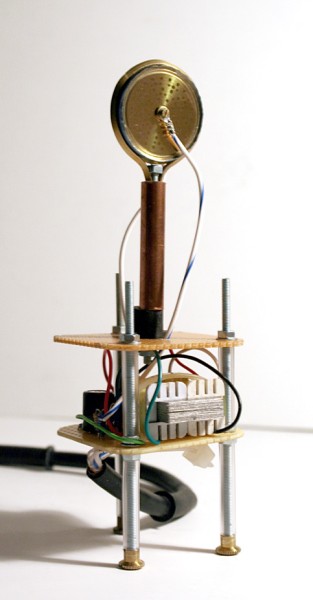

Here's the whole internal assembly. One good thing about it is that it holds together without the housing. Once it's finished you just loosen the screws below, mount it into the microphone body and fasten the screws again. The whole affair is held togetehr by three of the same long M3 screws I used for the capsule mount. The standoffs are just rubber tube which is dirt cheap and very easy to cut into any size you need. Plus the rubber tube is flexible which helps to keep the screws fastened and again helps to reduce rumble.

I should probably shorten those screws. But I'm thinking about putting some dampening material on the base plate, and those screws might be useful to hold it in place.

As you see, I decided to use one of those big ass ribbon mic housings. The main reason being the large basket. Once you take out the internal ribbon protection stuff, the actutal basket is pretty open and transparent, pretty much like a real M49. Despite its openness, pop noises are hardly a problem, even without a pop screen. A large open basket is still more protective than a small basket using dense material.

How does it sound? Excellent! Which, no doubt, is mostly due to Dale's M7 style capsule. I have a Gefell UM92S to compare to. The Gefell sounds somewhat darker, which to some extent is due to the tube circuit, but probably just as much due to the fact that the capsule is mounted in a smallish, less open basket. Another difference is in noise. A tube mic will usually be somewhat higher in noise, and the Gefell is no exception. My 49 style FET mic is dead quiet, even without a DC converter for proper 60V bias. On the other hand, right now it is cardioid only, so there's no extra noise from the rear diaphragm.

Anyway, big thanks to Dale for his capsule work!

Cheers,

Andreas

The capsule is a Dale M7, the transformer is one of those "BV-style" Giantbenny ones. They're about 10:1, so I decided on a simple KM84 style one FET circuit. There's nothing really new or particularly interesting about "my" mic design. The reason I'm showing it here is the mechanical part, which may inspire some of you guys. In particular the M7 capsule mount that some of you may be struggeling with. It took me a while to come up with a simple solution.

As you see, it's just a V-shaped brass profile bent to a kind of omega shape, which then slides into a copper tube. A long M3 screw presses down on the brass profile, thus fixing it. The screw of course is also used to fix the mount on the base plate, which is just perfboard. I used a rubber thingy which in fact was a capsule holder for a small electret mic capsule (any piece of rubber tube may do just as well). This rubber thingy makes the mount a little flexible which helps to reduce rumble.

Here's the whole internal assembly. One good thing about it is that it holds together without the housing. Once it's finished you just loosen the screws below, mount it into the microphone body and fasten the screws again. The whole affair is held togetehr by three of the same long M3 screws I used for the capsule mount. The standoffs are just rubber tube which is dirt cheap and very easy to cut into any size you need. Plus the rubber tube is flexible which helps to keep the screws fastened and again helps to reduce rumble.

I should probably shorten those screws. But I'm thinking about putting some dampening material on the base plate, and those screws might be useful to hold it in place.

As you see, I decided to use one of those big ass ribbon mic housings. The main reason being the large basket. Once you take out the internal ribbon protection stuff, the actutal basket is pretty open and transparent, pretty much like a real M49. Despite its openness, pop noises are hardly a problem, even without a pop screen. A large open basket is still more protective than a small basket using dense material.

How does it sound? Excellent! Which, no doubt, is mostly due to Dale's M7 style capsule. I have a Gefell UM92S to compare to. The Gefell sounds somewhat darker, which to some extent is due to the tube circuit, but probably just as much due to the fact that the capsule is mounted in a smallish, less open basket. Another difference is in noise. A tube mic will usually be somewhat higher in noise, and the Gefell is no exception. My 49 style FET mic is dead quiet, even without a DC converter for proper 60V bias. On the other hand, right now it is cardioid only, so there's no extra noise from the rear diaphragm.

Anyway, big thanks to Dale for his capsule work!

Cheers,

Andreas