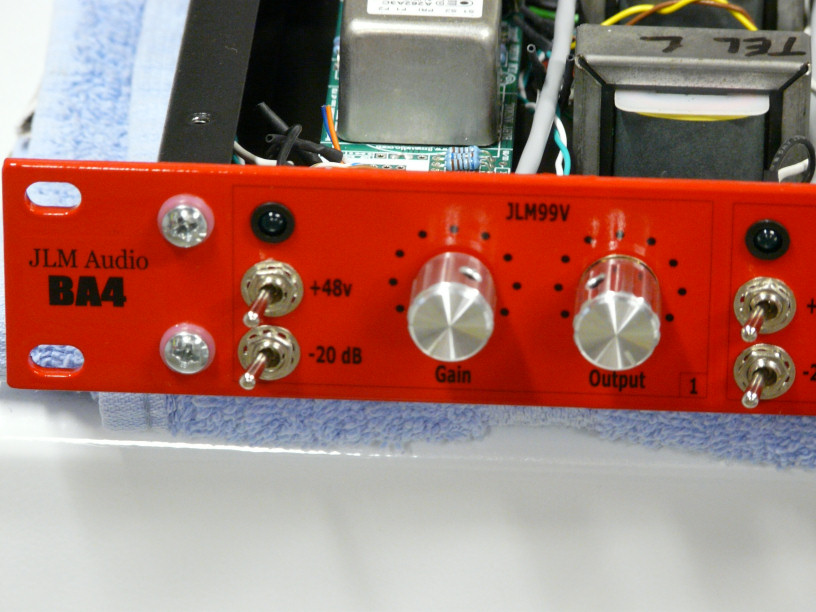

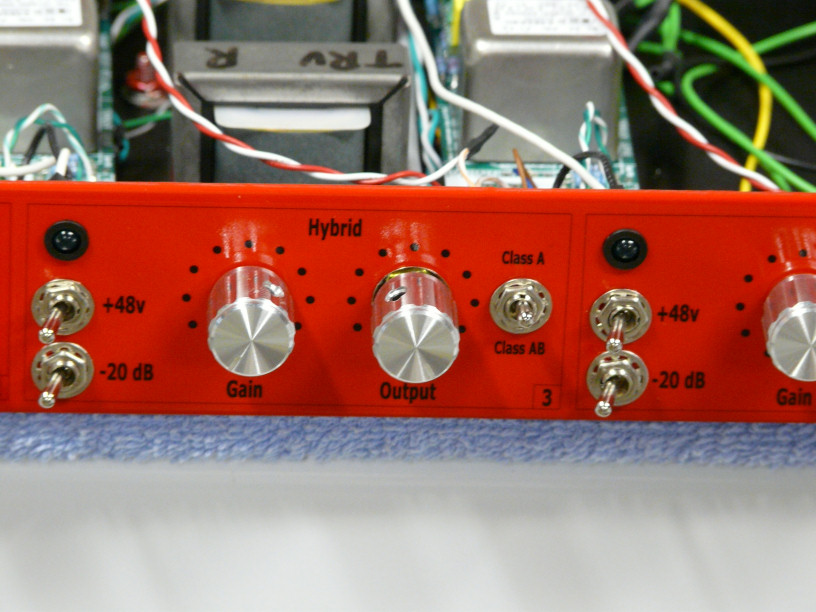

Yeah, I would prefer the lock washers on the other side too. The problem is the flat washer is grooved for these toggles, and I wasn't paying attention when I soldered them up. So some of them would have had the tab lip pointing in the wrong direction. It probably would have been OK, but it would have bugged me. Plus, those flat washers are much larger than the lock ring, and I thought it looked too big for the switch. Aesthetically it just didn't float my boat. Now if I could source some thin washers about the size of those lock washers...heaven.

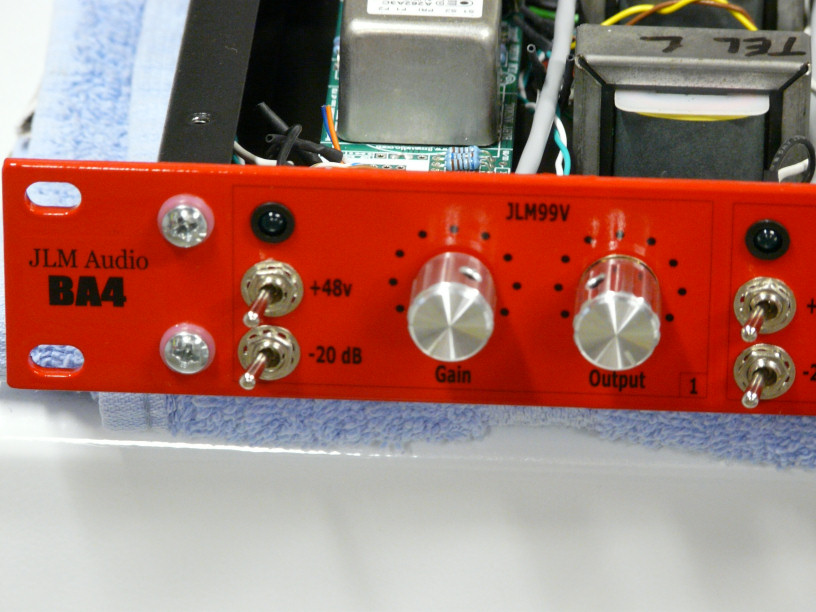

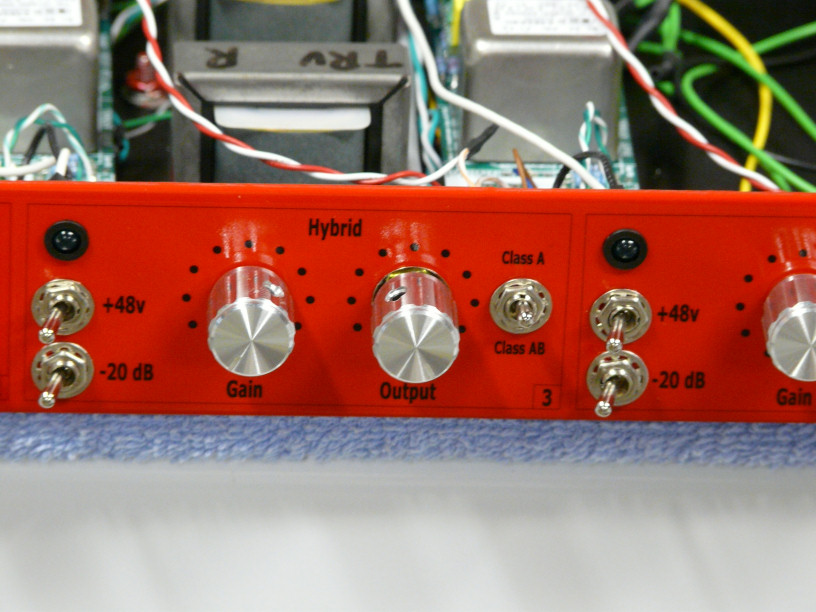

The front panel is all decals over a painted surface using Rustoleum enamel paint from Home Depot/OSH. I've gotten pretty good at spraying my panels, so this method works really well for me until I can find a decent silkscreening place that doesn't charge an arm and a leg for a panel like this. I mean when the panel costs more than the case, something is definitely wrong with that picture. Plus, I like the fact that I stuck to a true DIY and produced something that's pretty close to silkscreen results.

If anyone's interested, here's the process for doing the panels:

Design a layout in a CAD tool (I use DesignCAD, which is made by the same guys that do TurboCAD)

Print out the layout and overlay it on the front panel

Mark the holes with a punch

Drill the panel. I usually do square cutouts with a Dremel tool and lots of patience.

Prepare the front panel by sanding it lightly with 320 grit sandpaper. This roughs the surface up a bit and will allow the primer to adhere better.

Wipe down the panel with some acetone to remove any dust and ensure it is clean.

Spray the back portion of the panel with primer. Wait 20 minutes for it to dry to the touch and spray another coat of primer. Make sure you get the sides fully coated.

Wait 20 minutes and turn the panel over. Now spray the front panel. Wait 20 minutes and spray another coat of primer.

Now you let it sit for 24 hours so the primer fully cures. After it cures, examine the front for any imperfections. If there are any, then lightly sand them out with 320, and spray another layer of primer. Wait 24 hours before doing the color coat.

After 24 hours, now we shoot the color. Start with the back of the panel first. This time I only spray one coat of color because it's not as important as the front. Be sure to get the sides covered nicely as this will be important when shooting the sides for the front. If it doesn't cover properly at this point, it will be easier to chip when finished.

After 20 minutes, turn the panel over and spray the front of the panel. Wait 20 minutes and spray the second coat of color.

Wait 20 minutes more and spray one pass of clear coat. This layer should be fairly thin and is just enough to seal the top color coat. It's important to have one layer of clear prior to the decal application as it will blend better when spraying the final clear coats after the decals are applied.

Let the panel site for a full 24 hours. This will ensure that the paint has fully cured before going to the next step.

Now apply the decals. I typically do them in sections so it is easier to work with. I also print the decals with a guide in the holes so I know where the center is supposed to be an can use it to align everything properly. After you apply the decal, use some paper towel to remove any excess water and smooth out any bubbles that may have formed under the decal. Once all the decals are applied and there is no residual water for the process, set the panel aside and let it dry. I usually apply the decals in the early evening and let it sit overnight. In the morning everything will be fully set.

With the decals fully dried use an exacto knife to cut out the guide markers from the decals so that the holes are fully exposed. The decal will be nice and taught, so cutting the hole is fairly simple. Push down any exposed edges with the butt end of the knife, and use your pinky to push in the decal edges so it adheres to the inside of the hole you just cut. Once you have all the holes cut out, you're ready to shoot the final clear coat layers.

We don't care about the back of the panel for the final clear coats, so just put the panel up with the decal side exposed. Spray a single clear coat. Wait 20 minutes and spray the final clear coat. If it looks like there are still some spots that are not smooth, then wait another 20 minutes and spray a 3rd clear coat. I usually only do 2 final clear coats, but I have done 3 on some panels. It just depends, and it's really a matter of taste.

Let the panel sit for 24 hours so the clear coat is fully cured, and you're done! The whole process takes about 3 - 5 days depending on prep work and whether you make any mistakes in the process. The key thing to keep in mind is to keep your workspace clean. Any bit of dust can and will find its way onto your panel when you're spraying. If you take your time and follow these guidelines, you'll get really excellent results without too much hassle. And the final cost is the best part. The primer, color and clear cans of paint coats about $12, and the lazertran decals are about $2 a sheet. So for $15 you get a really nice panel. Not bad for a week of work.

Last tip: don't be too hasty to shoot the color or clear coats. If you don't wait the full 24 hours before going to the next step, shooting the paint will cause wrinkling and bubbling because the under layer has not fully cured. What happens is the solvents in the new layer dry faster than the ones in the under layer, and this has the effect of pulling the underlayer up, much like sucking liquid through a straw. The net result is you'll be stripping the panel down and starting over, and that is something you definitely want to avoid. Between the lacquer thinner to remove the paint and sanding to prep the panel for the primer layer again, it will add another day to the process. Best to avoid if at all possible.