Bruno:

Your right, I can't hear it, but I can see the current changes on an oscilloscope. And I can see the ammeter on my power supply move as music plays, but not on my meter. Dot mode is not my cup of tea, but fixes the current consumption perfectly you are right.

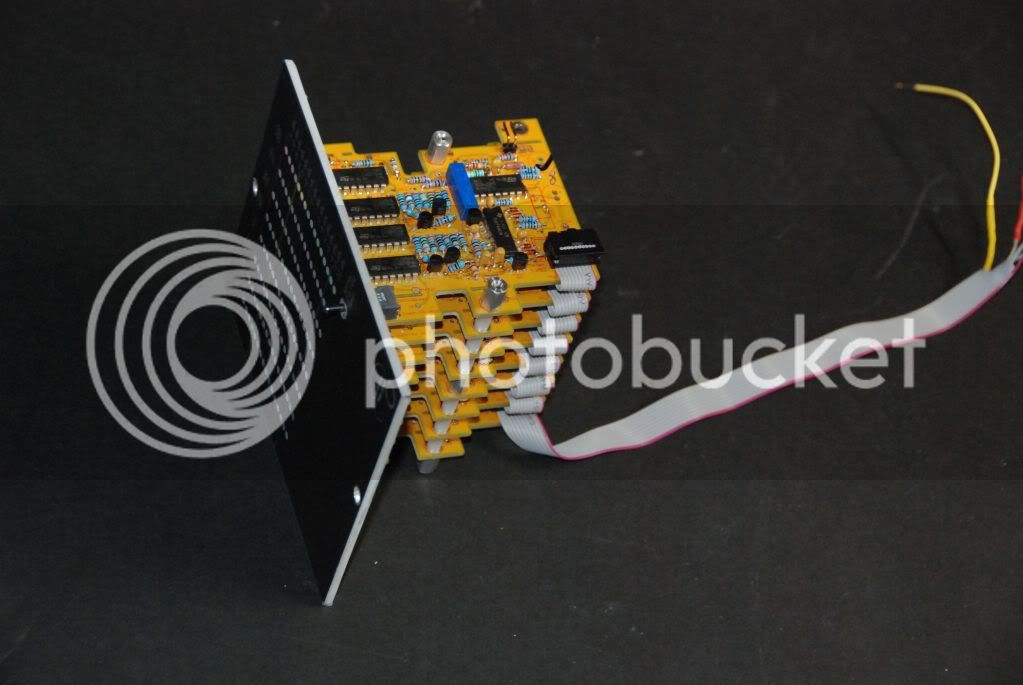

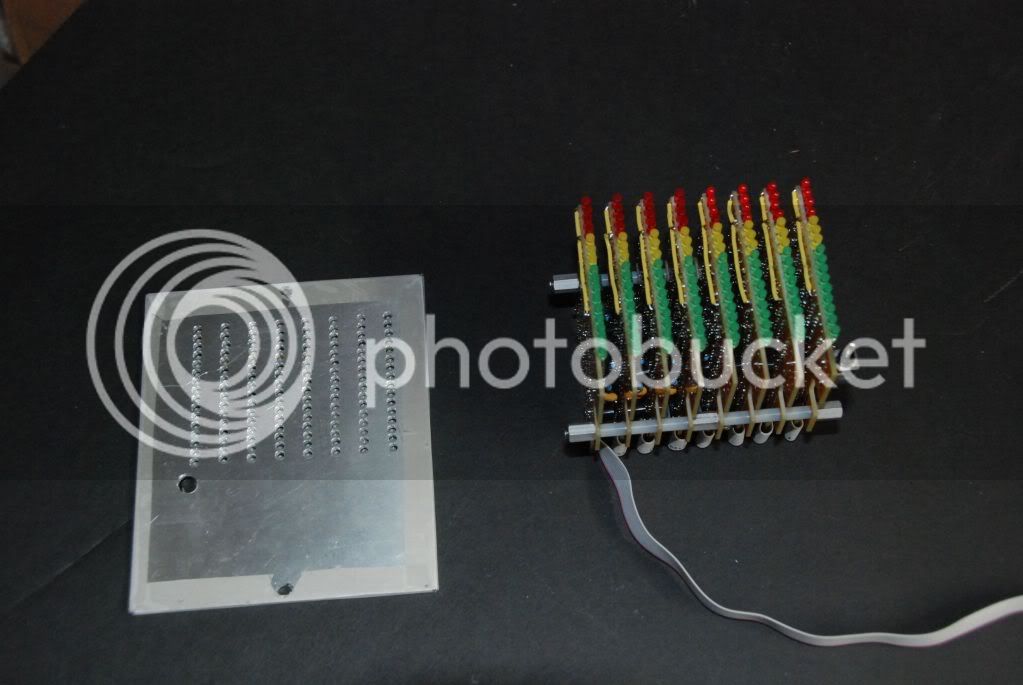

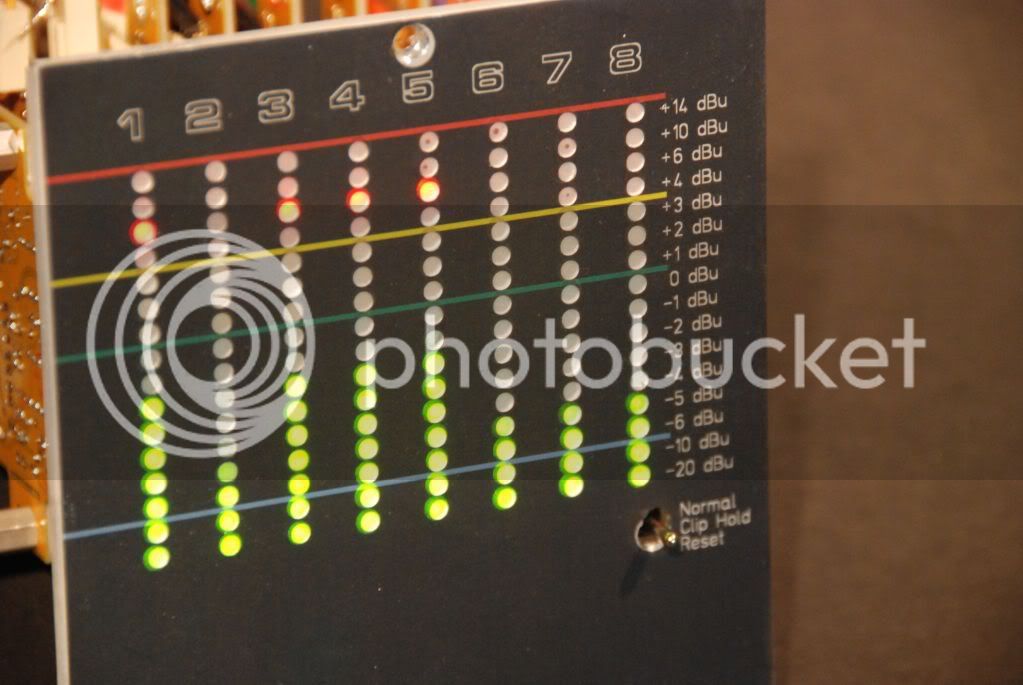

I need metering I can see from across the room on location. This card does that. Look above it also holds the highest instantaneous level hit (with very fast timing). I built it with a slot to be able to adjust your card, but it does a lot of other stuff too.

You can arrange an LMXX (For those that are unaware, Th LM3914 is linear, LM3915 is log, and LM3916 is VU) dot mode solves things, but I don't like it, I can't see the dots, and Bar mode can be built up to 10 LED"s in series... which fixes some of the current variation and lowers the current requirements, but I don't think it does 14 LED's and I want a custom scale..

I wanted to use a small amount of current, so I could put them in API modules without blowing the Amperage budget. I wanted "constant" current, so I could keep the power and ground clean. I wanted to use inexpensive parts, and I wanted to be able to control the dynamics and the scale and have a lot of resolution.

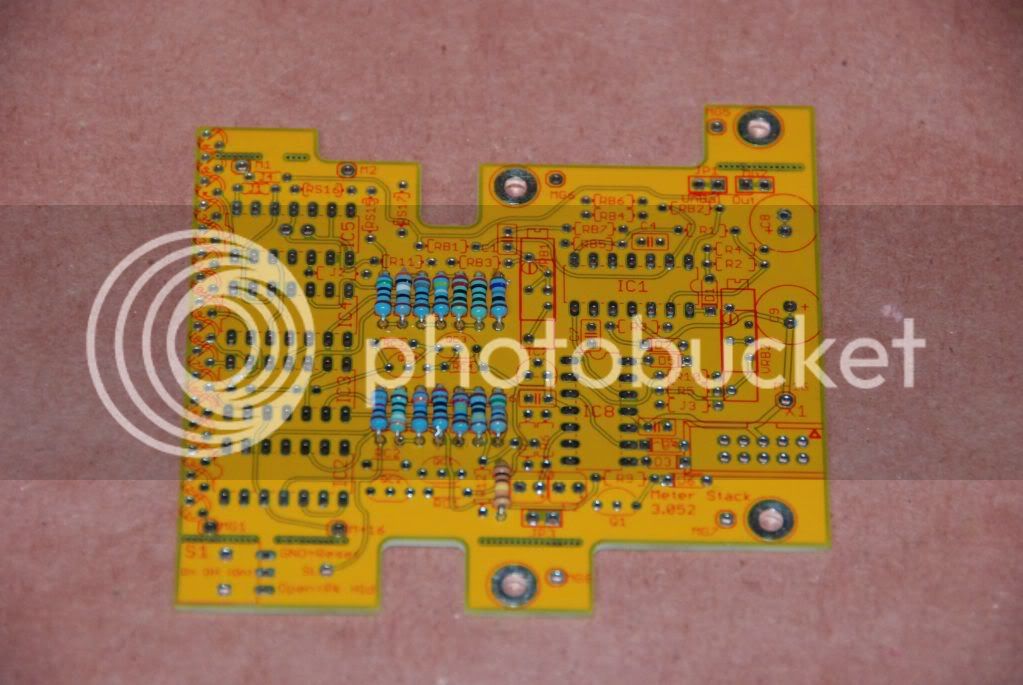

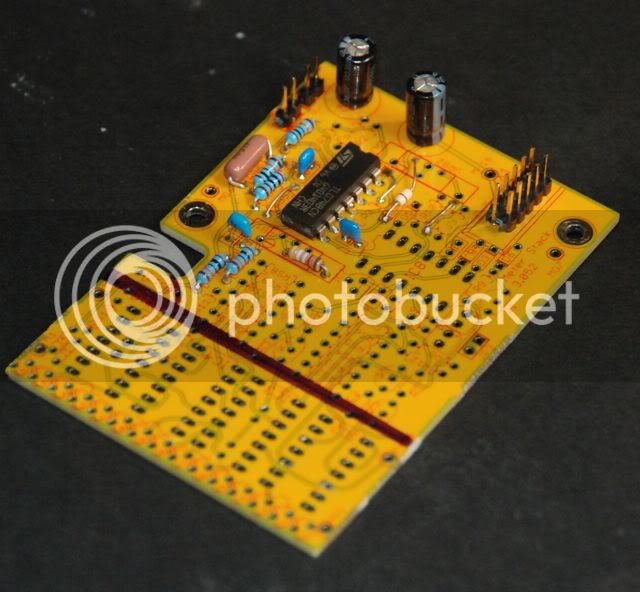

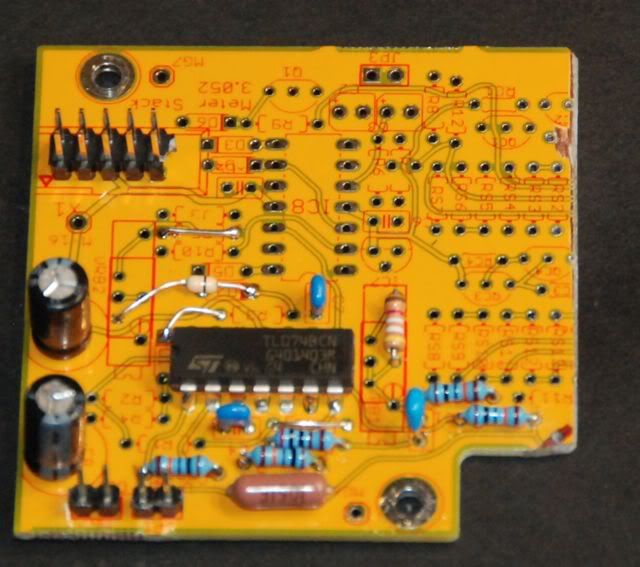

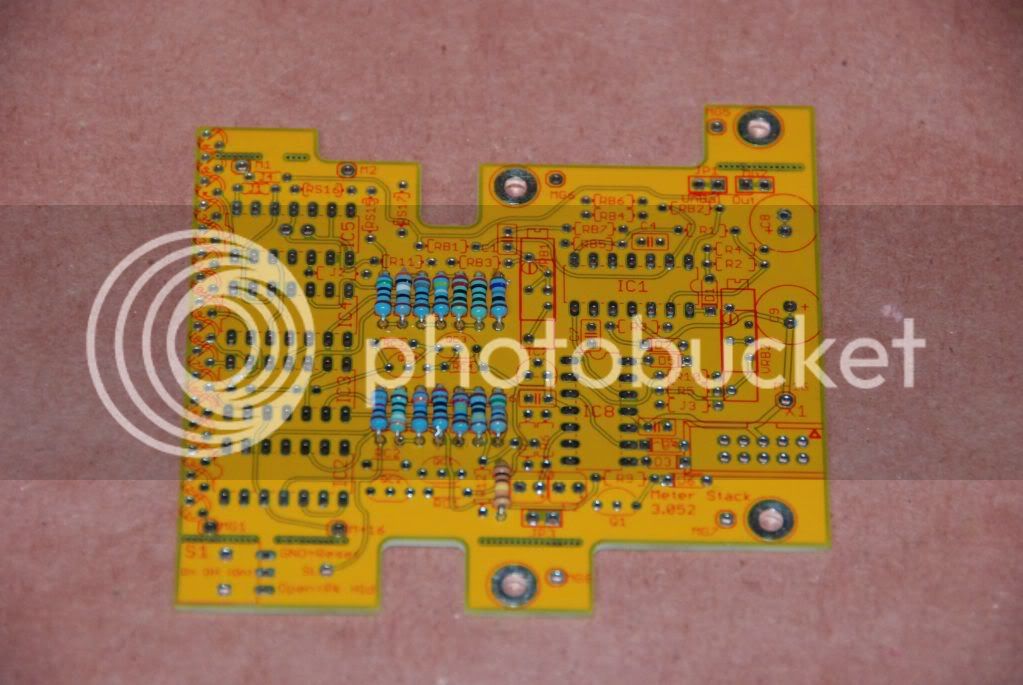

Anyway, I went through a slew of designes and prototypes, borrowing liberally, on breadboard (I won't blather on about temperature compensating log amps... but I could), and I came up with this, which is a simple series LED meter based upon LM339 comparators, which if you hook up the inputs to a voltage divider ladder, sink up to 16mA of current while they are off... till they switch on (open collector? I think they call it), at which point they stop sinking current and the next light switches on.

It runs in Bar mod with the LED's in series (up to 14 of them work fine on 32 volts) which I run using a 2 transistor current source.

"needs" Dot mode except for power issues.

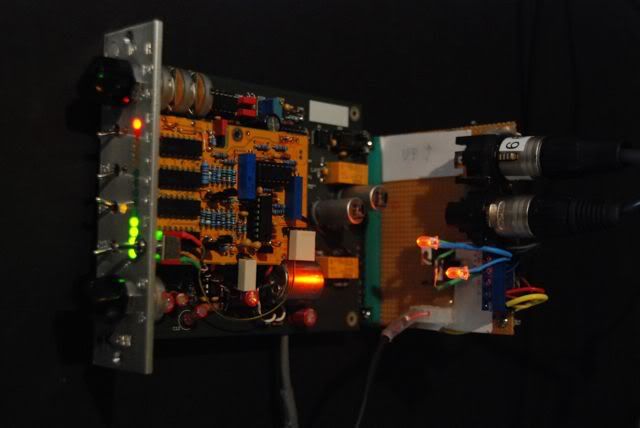

The first section is a balanced input section, using two virtual ground mixers so that the impedance is matched on both signal lines as well as you can match resistors. This section has adjustable gain. It is arranged similar to various application notes and is best described in the article by Walt Jung and Adolfo Garcia entitled "Op Amps in Line Driver and Reciever Circuits". It is not as good as the new, patented InGenious circuit from Mr. Whitlock, but it has a smaller parts count unless you buy the THAT IC he designed.

The following section is a precision rectifier, cloned off some desk meter, also with gain if you change resistances around, which I don't.

The following section is two pairs of two buffers for the upper and lower meter sections, these allow a peak hold capability and seperately configured dynamics for the two region meters. Upward response is separate from the decay of the meter, each controlled by different resistors one charging and one draining a capacitor for each section. I keep the "clip hold section" very fast, as fast as I can (no resistor), with slow decay and peak hold, and the lower section of the meter I run with relatively fast rising dynamics and slow decay, which allows it to respond in such a way as to indicate the general level. I used to have just one clip indicator, but now I have taken to using 3, at 4, 10 and 14 dB, all with clip hold, that way I can tell how close I got to my converters clip (which is 16dB above +4.

The scale is totally adjustable, using a resistor divider network, I admit it does increase the number of parts quite a bit (there are 17 of them on the small meter). My scale is set up for VU like with 3 level clip indicators with peak hold and reset. So -20, -10,-7, -5,-4,-3,-2,-1,0 in green, and 1, 2,3 in yellow, and 4,6,10,14 in red.

Rising and falling dynamics are controlled separately

It runs on +/-16 or more power and depending upon your current source resistor choice it uses 50mA all the time. Current source using 47 ohms 1 meter uses 50ma, but even less using 56 ohms... lights are still bright (I need to see it in daylight) and I am still trying lower values with it). I think you could run it on a single power supply, the comparators can handle it, but I have not tried. if you run 16 LED's with 1 clip light you get a faint dimming of the lower lights when the 15th light goes on due to the voltage drop. I can't see it if my supply is a solid +/-16.

If you break off the tabs on the card, and put in a couple of jumpers, it will replace the board in your (Bruno) 9k5 and 4k5 Preamps (the slot is so you can still adjust the pots on his board). It will do peak hold too but you need a On, Off, (On) switch panel mounted and it needs to be small, for Normal (on), Peak Hold (off) and Reset((on)). It converse a larger area of course but uses a lot less power, keeps the preamps within 120mA all the time, and gives me the dynamics that make sense for my converters.

In general, as a single 16 LED meter, you can mount a switch at the bottom that has a On-Off-(On) SPDT pcb mounted switch (I used NKK), middle is peak hold, up is normal and momentary down resets the peak.

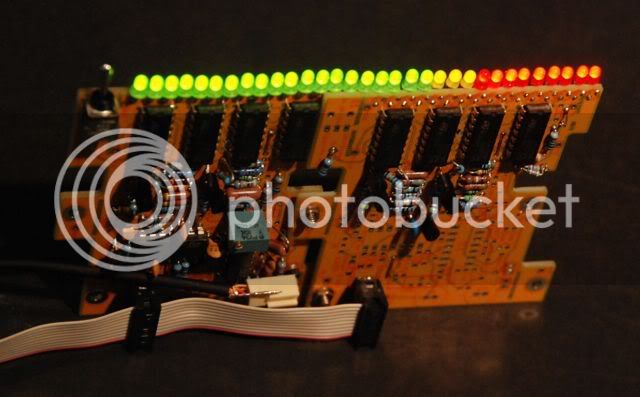

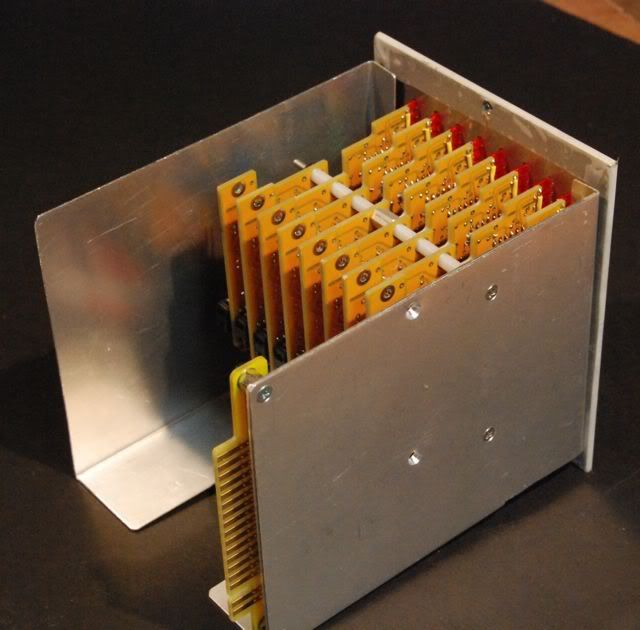

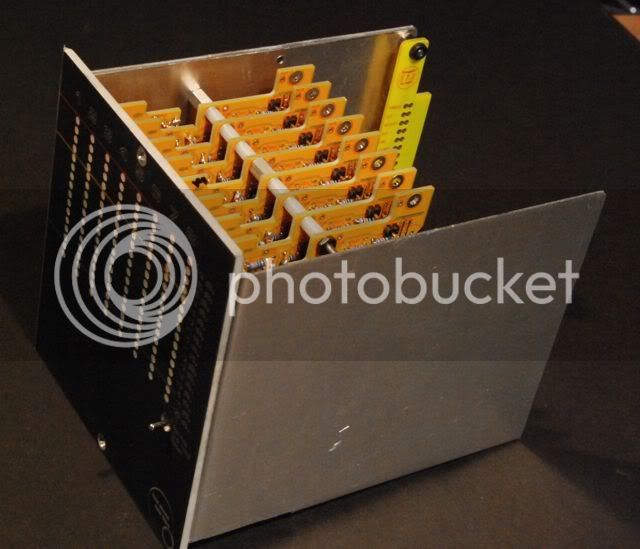

If you bold 2 or more together you can make stacks of them (I am testing out a dual now 32 lights, but I am out of LED's) but I don't believe there is a limit ((except to how much flux you want to breath).

It sits pretty low, and side by side you can space them comfortably with 3/8 inch standoffs... Closer if you want but it will get tight and you might have to do some parts selection or eliminate the trim pots (not really needed)

So I have this meter which will monitor my whole GDIY51x rack (actually, only 8 slots because it uses 3), in my mobile work, and in a lot of home project studio setups, good metering is just gone. if you are mixing in the box the only meter you get is what is on the converter, which is pretty poor on a lot of boxes.

If you don't build the meter component, you don't need to comparators, and a bunch of parts, and you can still use the balanced to unbalanced converter aspect of the card. There is an output jack mount for that.

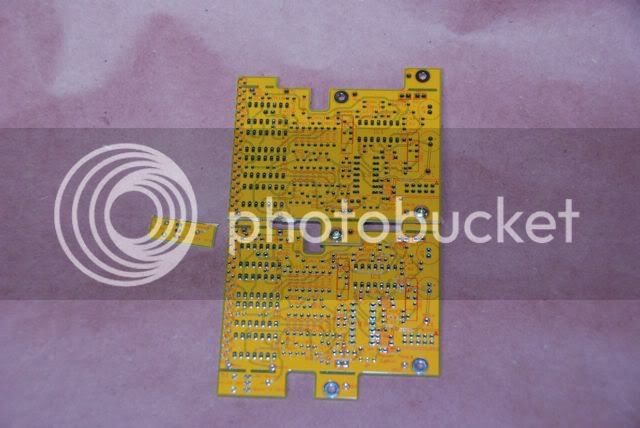

You can have a combination of individual and global resets using the reset line. The cards connect to one another using a 5 pin connector (but I use 10 pin IDC ribbon to do it because it is easy and available.) The 5 conductors are V+ Gnd V- (ground to reset) and a signal line to link a vertical stack of cards. There are jacks for input, unbalanced output and signal in. There is no meter out for analog meters, but you just connect that in place of R11.

If you build the debalancer, and the rectifier and the peak hold circuits, it will drive a galvanometer (analog meter) and it will do peak hold for you on the analog meter (maintaining the highest level of meter position using the sample and hold circuit). I haven't tried this yet, but it should work. You will also have a second buffer that can drive an LED with a single comparator (for a blinking clip light for instance).

Card is 3.1 inches high by 3.3 inches long intended to be mounted endwise to the front panel (but not necessarily). If you break off all the tabs it is only 2.3 inches high ( mode... 14 led's no switch).

Anyway, for me it fills the bill for metering I can see from across the room, but it could work added into many modules or racked equipment.

I gave a lot of thought to the scale I use (which as I say, is set by the resistor divider network, so this is just a personal choice). It basically has VU scale and Dynamics on the bottom half, but then has 3 very fast response lights on the top that show peak levels (+6 +10 +14) ... and they respond to really short transients... so if the 14 is unlit, I can be pretty sure I didn't clip, but the overall meter works like a VU