You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inductors for passive EQs...

- Thread starter alk509

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

khstudio

Well-known member

I'm sorry to butt in but I've been checking out this post & the ones about the Pultec & I'm just about ready to build and EQ. I would like to learn how to make or even buy a set of inductors for the Pultec.

Does anybody (or would anybody here) make them for a fair price? How hard is it to do myself... I don't have a month to learn all the ins & outs of inductors.

I do think I could do it but I'm not sure where or what to buy... I'm in the US.

Thanks,

Kevin

Does anybody (or would anybody here) make them for a fair price? How hard is it to do myself... I don't have a month to learn all the ins & outs of inductors.

I do think I could do it but I'm not sure where or what to buy... I'm in the US.

Thanks,

Kevin

OK, some more observations:

First things first: Metal screws are the way to go with these pot cores. They hold tension much better than the shitty plastic ones that ship with the cores. In fact, it actually almost brings the core up to spec in terms of AL! Here's how I got some repeatability: I have an adjustable-torque power drill, so I set it to the lowest torque setting, put a phillips screwdriver head in, and tightened the screw with it. Did it a couple of times and the inductance was practically exactly the same every single time. This morning I also checked a core that I left sitting last night with a metal screw tightened this way, and it measured EXACTLY the same as last night. So that solves that problem! :grin:

Also, don't waste your money on a counter if you're going to be winding coils with one of these Stanley hand-drills: The drill has a gear ratio of 56:15, in other words, 15 turns of the spindle turn the chuck exactly 56 times. So figure out how many times you need to turn the spindle for a given number of turns and skip the counter. It's more trouble than it's worth, IMHO, especially if you're not laying the wire down neatly.

Every coil winder should just get one of these Stanley hand drills. Once I figured out the gear ratio trick, winding a 300-turn coil took me all of 90 seconds! :shock:

Peace,

Al.

First things first: Metal screws are the way to go with these pot cores. They hold tension much better than the shitty plastic ones that ship with the cores. In fact, it actually almost brings the core up to spec in terms of AL! Here's how I got some repeatability: I have an adjustable-torque power drill, so I set it to the lowest torque setting, put a phillips screwdriver head in, and tightened the screw with it. Did it a couple of times and the inductance was practically exactly the same every single time. This morning I also checked a core that I left sitting last night with a metal screw tightened this way, and it measured EXACTLY the same as last night. So that solves that problem! :grin:

Also, don't waste your money on a counter if you're going to be winding coils with one of these Stanley hand-drills: The drill has a gear ratio of 56:15, in other words, 15 turns of the spindle turn the chuck exactly 56 times. So figure out how many times you need to turn the spindle for a given number of turns and skip the counter. It's more trouble than it's worth, IMHO, especially if you're not laying the wire down neatly.

Every coil winder should just get one of these Stanley hand drills. Once I figured out the gear ratio trick, winding a 300-turn coil took me all of 90 seconds! :shock:

Peace,

Al.

NewYorkDave

Well-known member

I'll have to check to see if the ratio on my ancient Stanley drill is the same as yours.

My counter is already bought and paid for, so I'm still going to try to rig something up. If nothing else, I won't have to really concentrate as much while winding.

Thanks for the posts. This will save me some work when I get around to winding my own.

So, what EQ are you building, anyway?

My counter is already bought and paid for, so I'm still going to try to rig something up. If nothing else, I won't have to really concentrate as much while winding.

Thanks for the posts. This will save me some work when I get around to winding my own.

So, what EQ are you building, anyway?

NewYorkDave

Well-known member

Mine is an old USA-made Stanley "Defiance." I'll have to check out the ratio...

khstudio

Well-known member

[quote author="analag"]http://www.mouser.com/catalog/625/713.pdf

all the inductors you need are in the link above.

analag[/quote]

That doesn't look right :?

I thought the Pultec has a multi tap :?:

all the inductors you need are in the link above.

analag[/quote]

That doesn't look right :?

I thought the Pultec has a multi tap :?:

Greg

Well-known member

Don't hijack alk509's inductor winding thread with specific info regarding Pultecs. I think this will be a great resource for general inductor winding. I have it bookmarked !!! :thumb:

Start a new thread for specifics about the Pultec.

Start a new thread for specifics about the Pultec.

khstudio

Well-known member

Sorry Greg... You don't have to jump all over me dude. I don't know much about inductors & thought they might have something in common, the EQ inductors & how to wind them. I've been scanning thru the different EQ posts to get an idea where to start & the inductors are the only thing stoping me from building one.

there is only one inductor in the EQP-1A.

the hi boost (inductor used here) is probably the least used section of the EQP.

everyone loves the bottom end, with the cut/boost trick.

look out for excessive capacitance with power inductors.

there is a Torwico p/n floating around here somewhere.

some folks say the Torwico was the stock part back in the day.

where is that inductor shootout thread with the MP3's?

the hi boost (inductor used here) is probably the least used section of the EQP.

everyone loves the bottom end, with the cut/boost trick.

look out for excessive capacitance with power inductors.

there is a Torwico p/n floating around here somewhere.

some folks say the Torwico was the stock part back in the day.

where is that inductor shootout thread with the MP3's?

Hey, I don't mind - hijack away! It is kinda nice to have different topics organized in different posts, though...

[quote author="CJ"]Torwico[/quote]

Wasn't that Toko? Or was it Wilco?... Damn, I always get those two mixed up! :?

[quote author="CJ"]where is that inductor shootout thread with the MP3's?[/quote]

Yeah, that thread kicked ass! If someone finds it, please bump it up?

So anyway, back on topic: Just as I decided not to use a counter, my counter arrived in the mail. And the guy actually threw two of them in there!!! :grin:

So now I have two beautiful Matsushita counters... I'll try to rig one up, maybe sell the other one in the BM.

Damn, I have a job interview tomorrow morning, but I just want to wind some coils instead of researching the company and all that stuff! :?

Peace,

Al.

[quote author="CJ"]Torwico[/quote]

Wasn't that Toko? Or was it Wilco?... Damn, I always get those two mixed up! :?

[quote author="CJ"]where is that inductor shootout thread with the MP3's?[/quote]

Yeah, that thread kicked ass! If someone finds it, please bump it up?

So anyway, back on topic: Just as I decided not to use a counter, my counter arrived in the mail. And the guy actually threw two of them in there!!! :grin:

So now I have two beautiful Matsushita counters... I'll try to rig one up, maybe sell the other one in the BM.

Damn, I have a job interview tomorrow morning, but I just want to wind some coils instead of researching the company and all that stuff! :?

Peace,

Al.

how much for the counter?

belt drive?

reset?

I'm sorry, I think it was Towico. Kind of a cross beyween Wilco and Toko. I have the Wilco cd, but have not been able to find the Toko disc.

belt drive?

reset?

I'm sorry, I think it was Towico. Kind of a cross beyween Wilco and Toko. I have the Wilco cd, but have not been able to find the Toko disc.

NewYorkDave

Well-known member

Nice counter, Al!

I bought this Redington beauty, a mech job with a reset. Just waiting for it to show up in the mail...

I bought this Redington beauty, a mech job with a reset. Just waiting for it to show up in the mail...

Greg

Well-known member

I wasn't trying to jump your shit khstudio... sorry if I came off like a jerk. I plan to build a Pultec one of these days.

[quote author="khstudio"][quote author="analag"]http://www.mouser.com/catalog/625/713.pdf

all the inductors you need are in the link above.

analag[/quote]

That doesn't look right :?

I thought the Pultec has a multi tap :?:[/quote]

You can use individual inductors and series connect them, my friend. It's the same thing done a different way.

http://www.cinemag.biz/inductors/inductors.html

http://www.sowter.co.uk/

click on Pro vintage and all you need will be right there.

Much options available, from low cost to expensive to experimental like these guys are discussing in this thread.

analag

all the inductors you need are in the link above.

analag[/quote]

That doesn't look right :?

I thought the Pultec has a multi tap :?:[/quote]

You can use individual inductors and series connect them, my friend. It's the same thing done a different way.

http://www.cinemag.biz/inductors/inductors.html

http://www.sowter.co.uk/

click on Pro vintage and all you need will be right there.

Much options available, from low cost to expensive to experimental like these guys are discussing in this thread.

analag

Just spent a good 5 hours winding a low end inductor for my passive EQ. I pretty much had to scrap all my calculations and go by trial and error. I lost count of how many times I had to just unwind the coil and start from scratch!

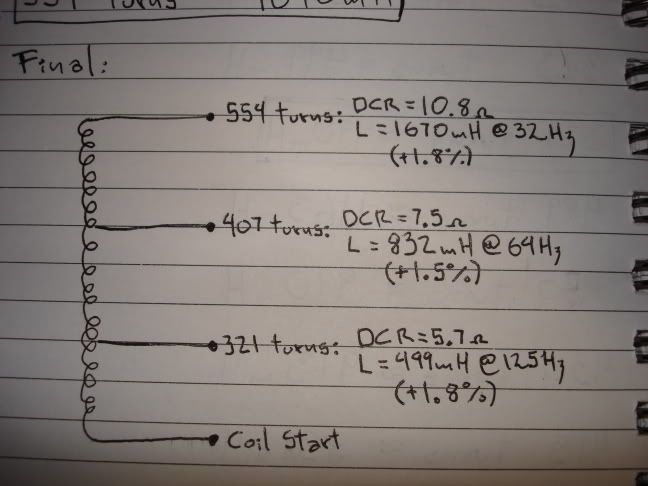

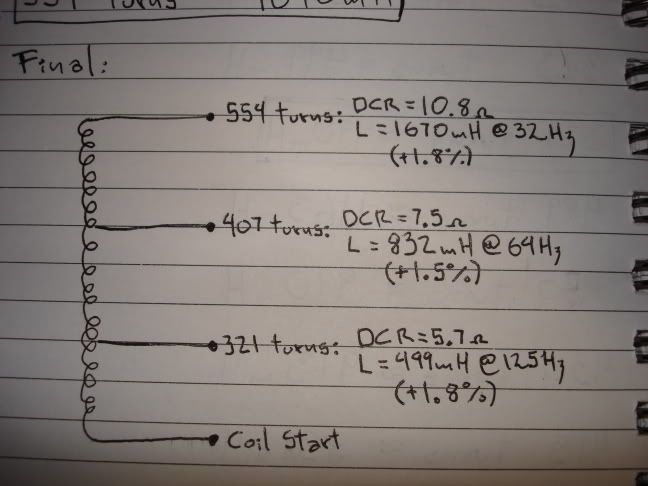

There's no way you can wind one of these suckers to tight tolerances with any degree of predictability, especially at the lower end of the audio spectrum - it drove me insane for a couple of days, but finally I just gave in, over-wound, measured, took some turns off, measured, took more turns off, measured, et cetera, until I had the values I needed. The final product:

As Chris predicted, once the final tap was wound, the inductance of the first and second taps increased slightly (by 1.8% and 1.5% respectively), compared to what I had measured them to be on their own.

DCR was reasonably low (11 Ohm total). The turns vs. wire size chart on Amidon's site was priceless in coming up with the thickest possible wire for the number of turns needed (29-gauge, in my case).

It was supposed to be a 1640mH inductor, with taps at 490mH and 820mH... Here's how it came out:

Tomorrow I'll wind this one a twin so I can make a stereo unit. Now that I have a better idea of the number of turns needed, it shouldn't take me nearly as long as this one! Then I have to do the same thing for the mid and hi band inductors........ :green:

Hope it inspires somebody to wind some shit! :thumb:

Peace,

Al.

There's no way you can wind one of these suckers to tight tolerances with any degree of predictability, especially at the lower end of the audio spectrum - it drove me insane for a couple of days, but finally I just gave in, over-wound, measured, took some turns off, measured, took more turns off, measured, et cetera, until I had the values I needed. The final product:

As Chris predicted, once the final tap was wound, the inductance of the first and second taps increased slightly (by 1.8% and 1.5% respectively), compared to what I had measured them to be on their own.

DCR was reasonably low (11 Ohm total). The turns vs. wire size chart on Amidon's site was priceless in coming up with the thickest possible wire for the number of turns needed (29-gauge, in my case).

It was supposed to be a 1640mH inductor, with taps at 490mH and 820mH... Here's how it came out:

Tomorrow I'll wind this one a twin so I can make a stereo unit. Now that I have a better idea of the number of turns needed, it shouldn't take me nearly as long as this one! Then I have to do the same thing for the mid and hi band inductors........ :green:

Hope it inspires somebody to wind some shit! :thumb:

Peace,

Al.

very cool!

i was thinking about my "copper magnet wire is part of the core theory" and remembered that copper is non ferrous, so it would not make good core steel.

the increase in inductance as you wind may be due to the fact that as you wind, the inner windings get compressed a bit, thus providing less leakage, and thus more inductance for that tap.

but copper may be slightly magnetic, i will have to look that up.

your numbers look good.

but check the inductance tomorrow.

i bet the numbers will be different. tempeture and meter error, etc.

divide inductance by T^2 to get a core constant:

1670/554^2 = 5.441 m3

832/407^2 = 5.023

and 499/321^2 = 4.843

Al number is not critical, it does not change the outcome nearly as much as turns, because the equation is quadratic in T.

so your Al number goes up with turns a bit.

probably due to less excitation current to magnetize core with more turns.

there is a slight knee you have to overcome at the bottom of the curve.

do not confuse the 12.6 hz and others with test frequency, right?

thats just for reference, right?

so if you want to add a tap, use core constant 5 with the desired inductance to get a turns estimiate. I bet it will be pretty close.

i was thinking about my "copper magnet wire is part of the core theory" and remembered that copper is non ferrous, so it would not make good core steel.

the increase in inductance as you wind may be due to the fact that as you wind, the inner windings get compressed a bit, thus providing less leakage, and thus more inductance for that tap.

but copper may be slightly magnetic, i will have to look that up.

your numbers look good.

but check the inductance tomorrow.

i bet the numbers will be different. tempeture and meter error, etc.

divide inductance by T^2 to get a core constant:

1670/554^2 = 5.441 m3

832/407^2 = 5.023

and 499/321^2 = 4.843

Al number is not critical, it does not change the outcome nearly as much as turns, because the equation is quadratic in T.

so your Al number goes up with turns a bit.

probably due to less excitation current to magnetize core with more turns.

there is a slight knee you have to overcome at the bottom of the curve.

do not confuse the 12.6 hz and others with test frequency, right?

thats just for reference, right?

so if you want to add a tap, use core constant 5 with the desired inductance to get a turns estimiate. I bet it will be pretty close.

Thanks, CJ!

I'll sit down at the bench again later today, and re-measure this sucker to see if/how much it changed...

[quote author="CJ"]do not confuse the 12.6 hz and others with test frequency, right?

thats just for reference, right?[/quote]

Errr... Not sure what you mean there. I measured the inductance of each tap at the frequency that they'll be working on in my EQ. So I measured the first tap at 125Hz, the second one at 64Hz, and the big one at 32Hz, using the measuring setup I described at the top of the thread. My thinking here was that it wouldn't be of much use to measure a coil's inductance at 10KHz (or whatever my crappy LC meter puts out), if it will be significantly different in-circuit (in a 32Hz filter)... Please, PLEASE don't tell me that was stupid! :?

Peace,

Al.

I'll sit down at the bench again later today, and re-measure this sucker to see if/how much it changed...

[quote author="CJ"]do not confuse the 12.6 hz and others with test frequency, right?

thats just for reference, right?[/quote]

Errr... Not sure what you mean there. I measured the inductance of each tap at the frequency that they'll be working on in my EQ. So I measured the first tap at 125Hz, the second one at 64Hz, and the big one at 32Hz, using the measuring setup I described at the top of the thread. My thinking here was that it wouldn't be of much use to measure a coil's inductance at 10KHz (or whatever my crappy LC meter puts out), if it will be significantly different in-circuit (in a 32Hz filter)... Please, PLEASE don't tell me that was stupid! :?

Peace,

Al.

Similar threads

- Replies

- 6

- Views

- 1K

Latest posts

-

-

-

-

-

-

Warm Audio WA-19 (AKG D-19 clone), mechanical HPF, phase issue?

- Latest: abbey road d enfer