rock soderstrom

Tour de France

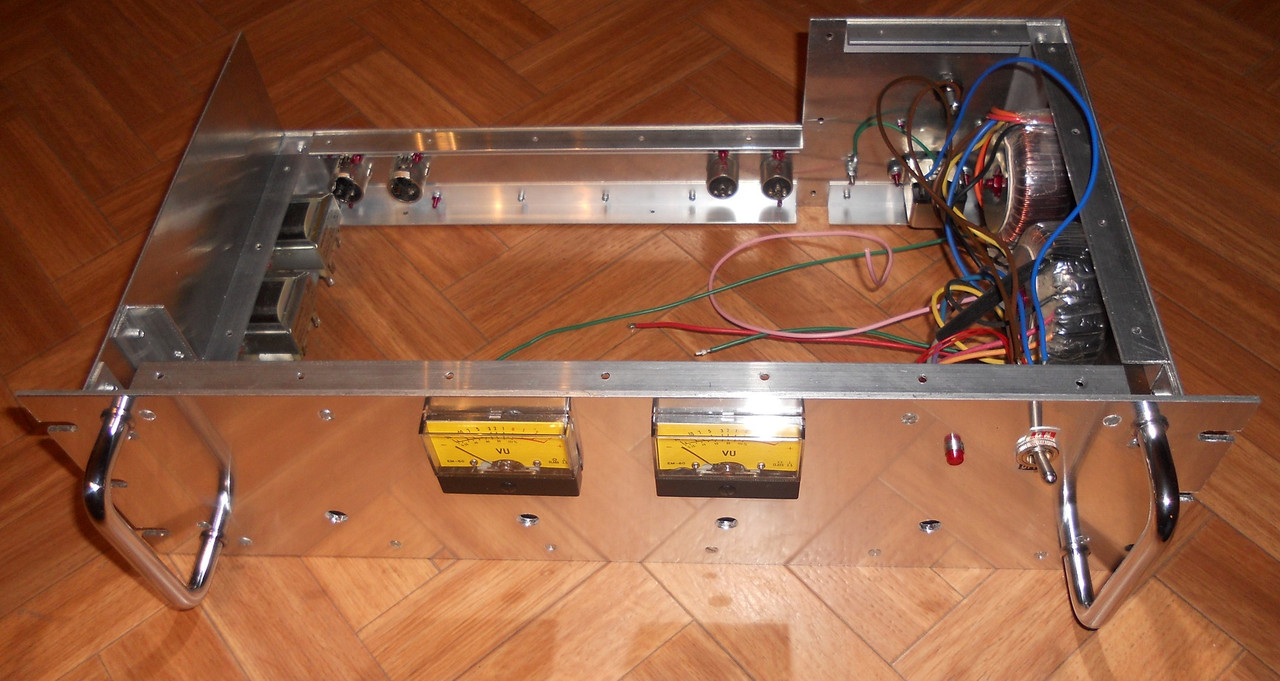

Yes, I know these things from my basic training, very handy. We even had one with a hydraulic drive, with that even I could cut sheet metal straight.What would be really useful is a large guillotine, then the cut edges are straight and at right angles.

Yes, it's really exhausting. I'm really bad with the jigsaw, which is why I bought the mini circular saw. With my DIY saw jig, I can actually cut straight now and the amount of reworking is minimalIt is very time consuming cutting with a jig-saw and then getting a straight edge to within a quarter of a millimeter with a file and a steel ruler.